Understanding Computer Numerical Control: Revolutionizing Manufacturing

Introduction

In the evolving landscape of manufacturing, Computer Numerical Control (CNC) stands as a cornerstone of modern production technologies. CNC, a method used to automate machining and manufacturing processes, has revolutionized the way we create everything from simple tools to intricate aerospace components. This blog post delves into the intricacies of CNC, its applications, and how it’s shaping the future of manufacturing.

What is Computer Numerical Control (CNC)?

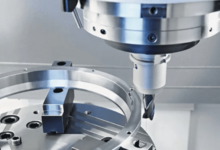

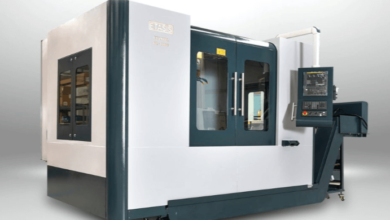

Computer Numerical Control, commonly referred to as CNC, is a technology that involves the use of computers to control machine tools. Machines like lathes, mills, routers, and grinders are operated through numerical control, where a software program is designated to control an object. The CNC system enables the precise control of speed, position, and feed rate of the tool, leading to high precision and repeatability in manufacturing processes.

How Does CNC Work?

The CNC process begins with a digital design created in a Computer-Aided Design (CAD) program. This design is then converted into a numerical code, usually G-code, suitable for the CNC machine. The G-code provides detailed instructions on how the machine should move, how fast, and through what paths. The CNC machine reads this code and executes the operations to produce the part exactly as designed.

Advantages of CNC Machining

Precision and Accuracy: CNC machines offer incredibly high precision and consistency, essential for complex or intricate parts.

Efficiency and Productivity: With CNC, production can be faster and more efficient, as machines can operate continuously with minimal supervision.

Flexibility: CNC machines can quickly switch between different production specifications, making them ideal for custom and varied manufacturing needs.

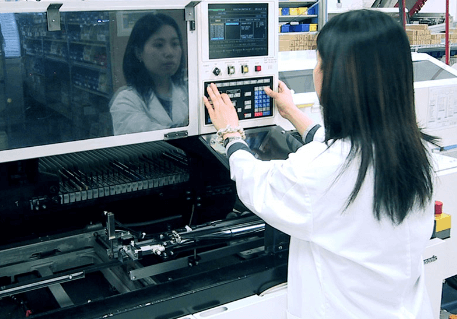

Safety: Since the process is automated, the risk of accidents associated with manual machining is significantly reduced.

Applications of CNC Technology

CNC technology finds applications across various industries:

Aerospace: For manufacturing complex aircraft components with high precision.

Automotive: Used in producing engine components, custom parts, and prototypes.

Healthcare: In creating medical devices and prosthetics with high accuracy.

Metalworking and Woodworking: For crafting intricate designs and patterns.

The Future of CNC in Manufacturing

The future of CNC is closely tied to advancements in technology. Integration with the Internet of Things (IoT), Artificial Intelligence (AI), and automation is set to further enhance the capabilities of CNC machines. This integration will lead to smarter, more efficient production lines capable of predictive maintenance, real-time monitoring, and even more complex manufacturing tasks.

Conclusion

Computer Numerical Control has become an indispensable part of modern manufacturing. Its ability to produce complex and high-quality products efficiently and safely makes it a preferred choice in various industries. As technology continues to advance, CNC will likely play an even more significant role in shaping the future of manufacturing. Whether it’s in small custom workshops or large-scale industrial settings, CNC technology is undoubtedly here to stay, continually pushing the boundaries of what’s possible in manufacturing.