What is a VMC machine used for?

Introduction to VMC Machines

What Makes a VMC Stand Out?

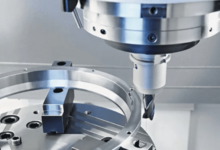

A Vertical Machining Center (VMC) is primarily distinguished by its vertical orientation of the spindle. Unlike horizontal machining centers, VMCs allow gravity to assist with the removal of metal chips during the machining process, which can lead to more efficient operations in certain scenarios.

Core Components of a VMC Machine

At the heart of a VMC are several critical components:

- Spindle: The tool holder that performs the actual cutting.

- Table: Where the workpiece is mounted.

- Control Panel: Allows the operator to program the machine’s movements and actions.

How Does a VMC Machine Operate?

The operation of a VMC involves precise computer control, where pre-programmed software dictates the movement of the tools and table. The ability to program operations allows for high precision and repeatability in production runs.

Applications of VMC Machines

VMC in Aerospace

In the aerospace industry, the precision offered by VMC machines makes them ideal for manufacturing complex components like engine mounts, and control panels.

Automotive Uses

From engine components to chassis, the robust capabilities of VMC machines help in producing complex geometries required by the automotive industry.

General Engineering

VMC machines are versatile tools in general engineering, capable of producing a wide array of parts with high precision.

Advantages of Using VMC Machines

Achieving High Precision

The accuracy of VMC machines is unparalleled when it comes to producing intricate and detailed components.

Enhanced Efficiency

VMC machines can operate continuously without sacrificing the quality of the output, significantly enhancing productivity.

Versatility Across Materials

VMCs can handle various materials including metals, plastics, and composites, making them valuable in diverse manufacturing environments.

Choosing the Right VMC Machine

Factors to Consider

- Size and Power: Depending on the size of the materials and the type of jobs.

- Software Compatibility: Ensures the machine can integrate smoothly into your existing operations.

Popular VMC Machine Models

- Haas VF Series

- Mazak VCN Series

Maintenance of VMC Machines

Routine Maintenance Checks

Regular inspections and servicing can prevent breakdowns and extend the lifespan of a VMC machine.

Tips for Professional Maintenance

- Lubrication: Essential for all moving parts.

- Alignment Checks: Ensure all components are perfectly aligned.

Future Trends in VMC Technology

Increasing Automation

Future VMCs are likely to feature more automated functions, reducing the need for human intervention and enhancing production efficiency.

Advancements in Software

Upgrades in software will continue to make VMCs more user-friendly and capable of more complex tasks.

FAQs

What materials can a VMC machine handle? VMC machines are adept at working with a wide range of materials, from soft aluminum to hardened steels.

How does a VMC machine differ from an HMC? The primary difference is the orientation of the spindle. VMCs have a vertical spindle, and HMCs have a horizontal spindle.

Is a VMC suitable for small-scale production? Yes, VMCs are excellent for both small and large-scale productions due to their scalability and versatility.

Conclusion

VMC machines are pivotal in the landscape of modern manufacturing. Their ability to handle complex tasks with precision and efficiency makes them a cornerstone in many industries. As technology evolves, so too will the capabilities of VMC machines, ensuring they remain at the forefront of manufacturing technology.